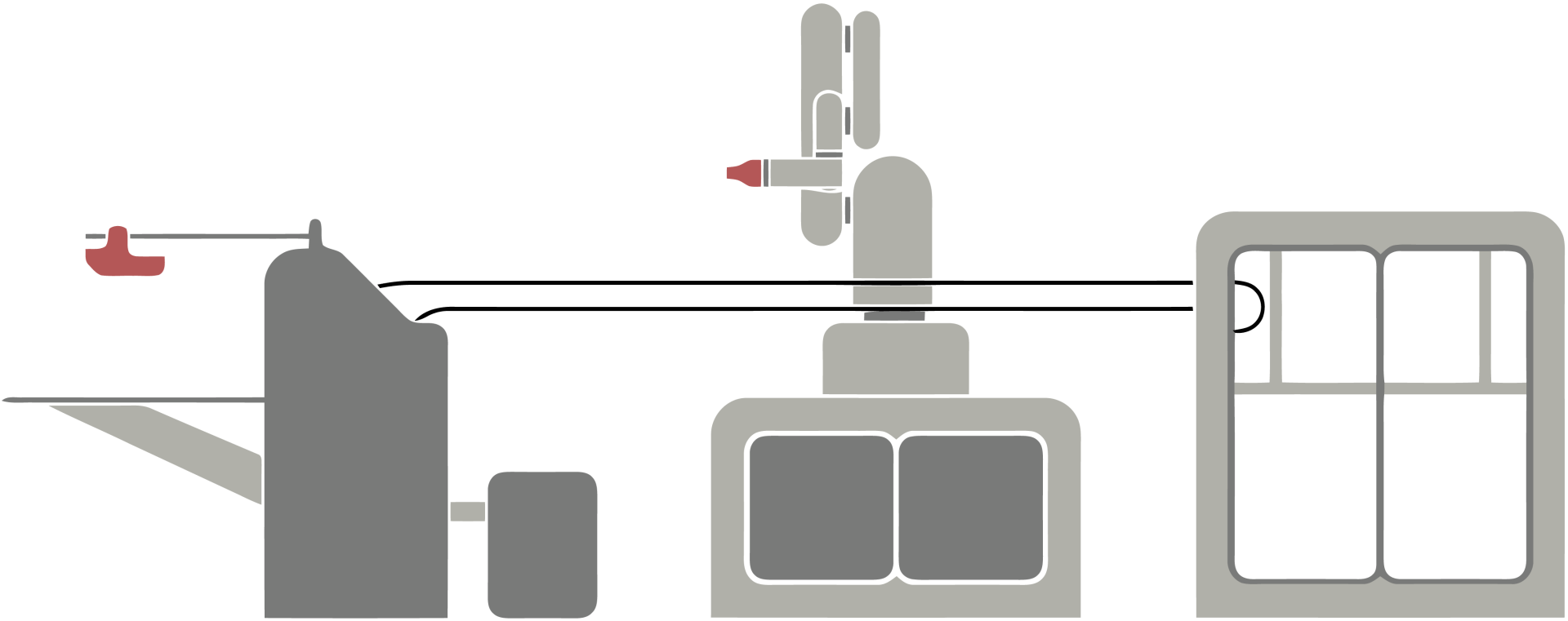

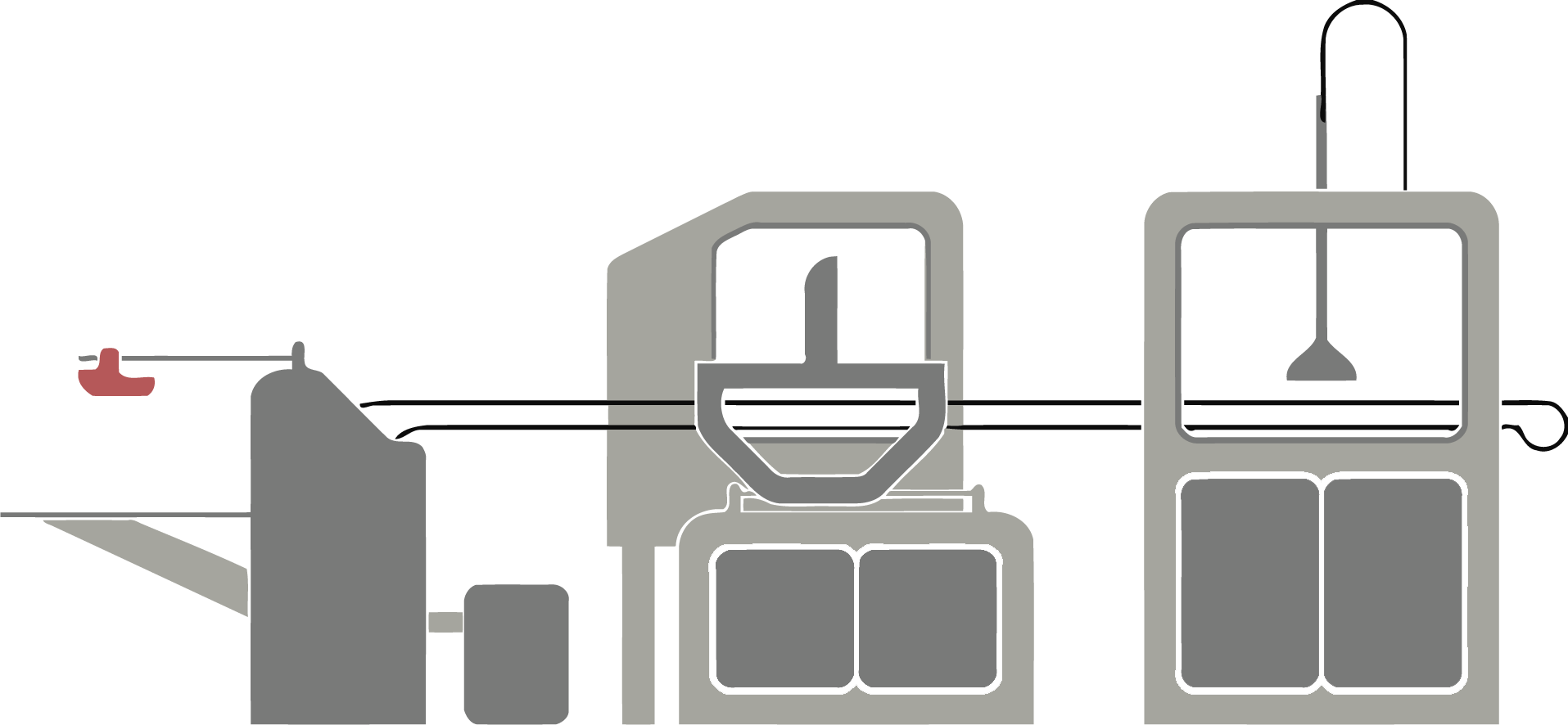

When a new machinery arrives into the production process there are many aspects to consider: learning time, productivity, maintenance time, etc.

Our experience let us to know the importance of the time and of the timing, therefore we believe that the customer should be able to use the machine since the installation date, that the machine should be clean and simple in order to reduce the maintenance time to the minimum, that every aspect of the production should available to be analyzed by the customer in order to optimize the work processes.