RETURN ON INVESTMENT

Help Building The Future

OVERVIEW

SATE

builds its machines to last longer and supports its customers whenever they need.

SATE's lines not only have a less expensive maintenance cost due to the structural simplicity and clarity in designing choice but are even energy saver with their patented energy recovery system.

Who (what)

is ROI?

For every investment you will want to know how long it will take to recoup your initial investment and how much that investment can be profitable.

The ROI (Return On Investment) calculations can give you an important index to understand it.

Why you ll' want to

use the ROI?

The ROI is an important instrument that can help you to to evaluate an investment, and is a key part of the vetting process.

The ROI calculations can give you much more informations than the simple time needed to recoup the initial investment; for example you can compare the efficiency of a future investment on the automation of a production process upon the current status of your company in order to evaluate if it will be effectively profitable, or you can compare two possible investments to decide which is the more advantageous.

You only need to remember that because ROI can be made with a lots of factors you have to compare ROIs made with the same factors.

How

to calculate

a ROI?

Step 1: Calculate total cost of the new equipment

When purchasing automated packaging equipment, you must take into consideration more than just the price tag on the machine. Your ROI calculations will be most accurate if your equipment cost represents the TOTAL COST OF OWNERSHIP including factors like:

- Equipment purchase price

- Freight costs

- Commissioning and installation costs

- Training costs

- Annual maintenance and parts expenses

- ...

These costs will vary widely and are hard to estimate, so we recommendCONTACTING A PACKAGING EQUIPMENT MANUFACTURERto request more information about machine costs specific to your application and business needs.

Step 2: Calculate labor with and without automation

First, determine the current fully loaded wage per hour for your packaging staff. This includes not only rate of pay, but the cost of benefits like insurance, paid time off, and other employee perks.

Next, determine how your labor costs would change with packaging automation. Your fully loaded wages per hour will likely not differ, but the number of employees required after implementing automation will change. Often this means the number of employees required to run a packaging line will decrease, sometimes by half or more.

Step 3: Calculate efficiency factors with and without automation

Packaging efficiency calculations begin with knowing how many packages are currently produced annually and what your profit per package is in dollars (or your local currency).

Then, using the specifications provided by packaging equipment manufacturers (check out their website or give them a call), you can input how many packages you could expect to produce after implementing automation. Throughput specifications are often represented as bpm (bags per minute) or cpm (cycles per minute). Multiplying this number by the hours spent packaging per day, the number of days per week, and operational weeks per year will give you an annual estimation.

Step 4: Factor in any miscellaneous expenses unique to your business

This should include every cost directly connected to the use of the machine like electrical power consumption, compressed air used, the changeover time needed to prepare the machine to realize a different product, the tools' cost, and more...

To make the ROI make sense, you need to include as many factors as you can, that can influence your benefit not now, but in the future!

Because of that, the ROI is really restricted to the company which is made for.

Step 5: Perform return on investment calculations

Simple Return on Investment (ROI) formula

A standard definition of ROI is the ratio of a benefit or loss made in a fiscal year expressed in terms of an investment and shown as a percentage. In packaging equipment terms, the ROI formula is as follows:

(Net benefit or loss generated by new equipment / Total new equipment cost) x 100

As an example, if you are considering purchasing a packaging system for $200,000 and predict a net annual benefit of $150,000 (via labor savings and profit from increased throughput), your return on investment will be:

($150,000 / $200,000) x 100 = 75%

Payback period (PBP) formula

The payback period calculates how much time it will take to recoup the initial investment. In packaging equipment terms, the payback period formula is as follows:

Total new equipment cost / Total periodic benefit realized from new equipment

Using the same example above of $200,000 equipment cost and $150,000 net annual benefit, the payback period will be:

$200,000 / $150,000 = 1.3 years

Let us help

you to

start

ROI Analysis

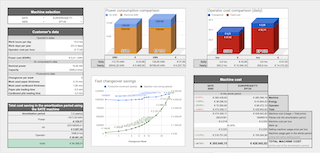

In SATE we believe that an accurate ROI can really guide you thru the choice of the best investment for your company.

Sometimes can be a real effort to evaluate pro and cons of various options and is a very time expensive activity.

We know it and therefore, SATE can offer a ROI analysis service in order to help our customer to do the right choice to optimize their investment.