INNOVATION LEADING

A continuous search for new technologies, their application and the development of advanced production systems

OVERVIEW

SATE

adopts a completely innovative approach to solve all the classic problems affecting the automatic rigid box machines, both during construction and at the start of production of boxes.

Innovative Solutions

our dreams, our legacy, your future

A continuous search for new technologies, their application and the development of advanced production systems is what distinguishes the innovative character of SATE. The technologies used by SATE reflect the latest solutions in the spirit of acceleration and production refinement that has allowed us to lead the market.

Innovation is the driving force behind this mechanism and in SATE it merges with the need to overcome the future challenges imposed by the economy. A mission that we set ourselves to overcome not only through the creation of modern and exclusive machinery but by improving and updating the production process itself.

Advanced Engineering

like germans, but with the sense of humor

R&D Team

A dedicated internal development team is the choice of SATE to keep growing ideas see the light.

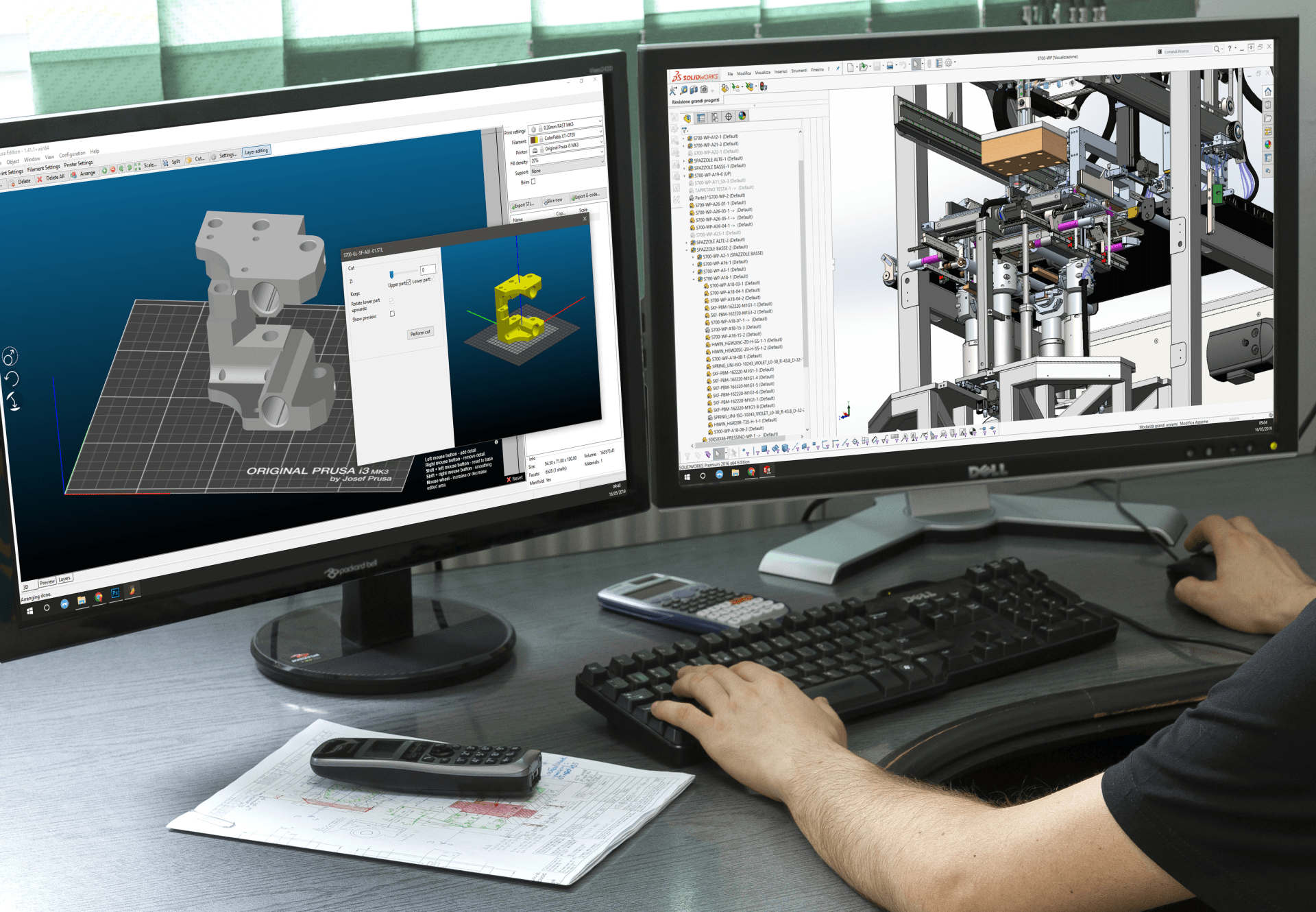

The latest software and hardware technology work together with human brains to increase productivity and functioning assurance.

Latest technologies

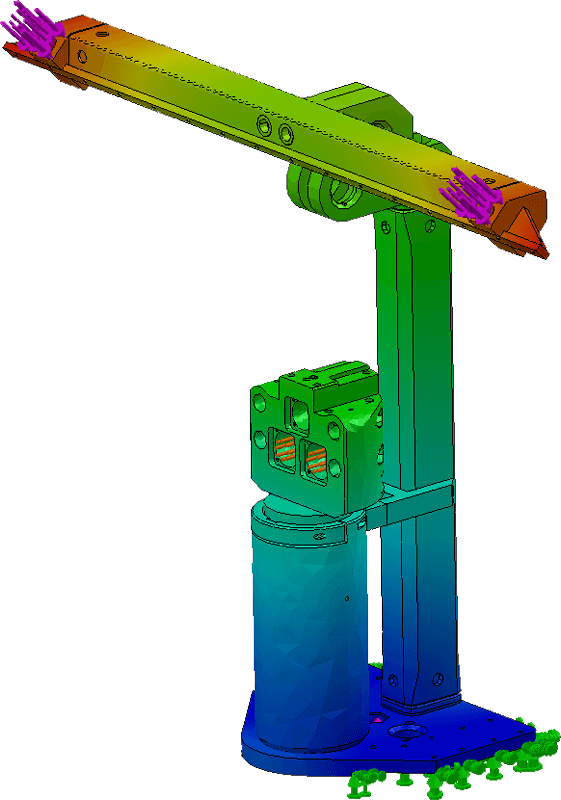

Every single detail of the machines SATE produces is controlled with simulation software and in reality with tests on the prototypes.

The production starts only when we can guarantee the reliability of each component and, to be even more sure about it, we test it again.

The secret of a solid, reliable and durable machinery is that there are no secrets between manufacturer and customer.

Simulation at his best

Our R&D department use the best tecnology to simulate every aspect of your machine so it can be more reliable, more efficent and faster.

This is possible thanks to a modern and proprietary software simulation model capable to reproduce the production workflow of our automatic rigid box machinery from the first start to a continuative production, passing by multiple format change. To be sure that everything works flawlessly we even make some real simulation on the actual product and manually adjust the little details that can cause imperfections.

Know-How

our high tecnology at your service to simplify and improve your work

Years of improvement

With more than 60 years of experience SATE is one of the oldest company in this market and the most innovative one.

SATE has patented, over the years, more than thirty innovations about paper and cardboard manufacturing of which more than sixteen only for what concerns the latest automatic rigid box making machines like the S line.

Experience on field

SATE doesn't sell machines, we build them from scratch improving every little detail compared to the previous model, so we know where to put hands in case of a technical intervention.

SATE is always ready to assist you during the starting process and at every need with a team sent on field.

Materials Study

the force of eachone is the force of all

Metal

Nothing is more solid and durable than metal: this is why every SATE machinery is made for the most by this incredible material.

The whole frame of each SATE machine is made by pure powder coated steel, meanwhile the most important components are made by a wide range of metallic elements and alloys such as aluminum 7075, bronze and brass.

Plastic

There are pieces that not only don't need the strength and hardness of metal but can result in reducing performances. Plastic is an excellent aid for consumable parts that need frequent and low-cost replacement.

SATE uses POM (Delrin®), UHMWPE (polyzene) , ABS and PLA depending on use area and piece characteristics.

Paper

SATE likes paper. And cardboard. And boxes.

As a rigid box machinery producer we are involved in the whole process of paper transformation trying our best to improve the industry with newer and better solutions.

In partners we trust

Like any other big company out there, SATE needs to trust some suppliers that can guarantee the same perfection standards that SATE wants to provide to its customers. A chain is as strong as its weakest ring, and a continue quality checks means great products.

All of our supplier agree with ISO 9001 norm to guarantee to us and to you the best quality possible.

Environmental Friendly

a little step for a man, a BIG step for humanity

Sustainability

SATE cares about our planet and chooses environmental friendly solutions to produce and distribute its products.

From nature surrounding the factory to production waste recycling, SATE is committed to sustainability. Paper and cardboard waste isn't a problem anymore: production tests and pre-production setting up are made with recycled and reusable materials with water based prints.

Compliance with the legislation in place is not sufficient to describe SATE commitment to the environment.

A new era

The new era of technology allows SATE to reduce the paper waste keeping all the mechanical project digital.

3D printing is used to avoid prototyping errors on less recyclable materials thus reducing material waste and speeding up the whole process.