LUXURY BOXES

High quality boxes can make the difference

OVERVIEW

The luxury packaging market is a growing market that constantly demands quality improvements and new solutions to presents the final product at its best.

Rigid Boxes

Thanks our partners we are setting new standards for rigid boxes and luxury packaging in general. When you find a box surprisingly well made you have good chances it has been made by a SATE automatic rigid box machinery.

Differences in Rigid Boxes

X T H, nope, not an alien code

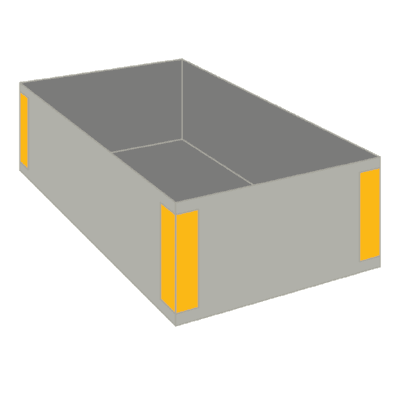

X

The most common box format is, maybe, the cross box or X: it's easier to manufacture and offers good stability and performance.

The simple X box can be produced at higher rates than the other two resulting in the best quality for price performance.

It's chosen by a large number of sectors included but not limited to luxury shoe, perfumes and cosmetics industries, high end wine and vinegar and so on.

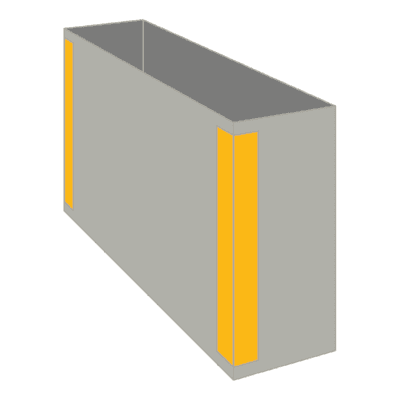

T

A T box allows a reduction of waste whenever an high and narrow box is needed thanks to its shape easier to combine during the die cutting process.

This box has a less stable bottom than the normal cross one, but it's cheaper to manufacture.

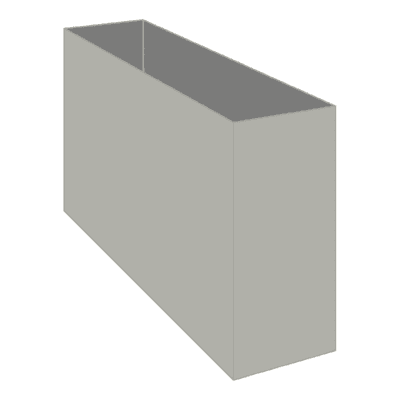

H

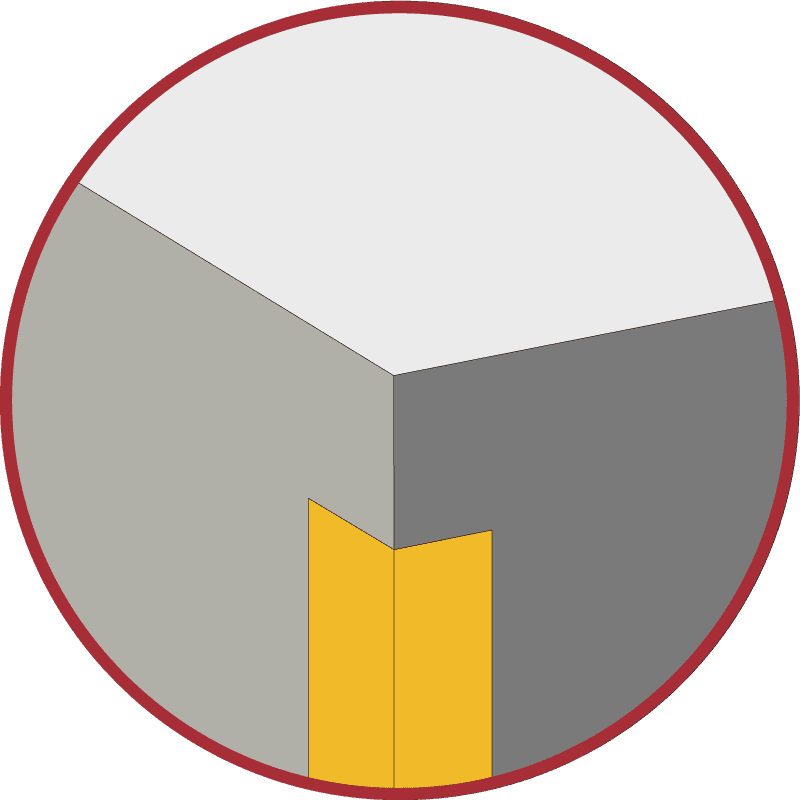

As for the T box, an H shape is a good choice when the resulting box is high and narrow thanks to the hot-melt system that glues to layers of the narrow side together creating a stronger bond on that side.

The cons of this system are: an unsealed space between the bottom and the narrow sides and double thickness on the narrow sides too, due to the gluing process.

Grooving Boxes: Premium Packaging

a new standard in luxury

Main differences

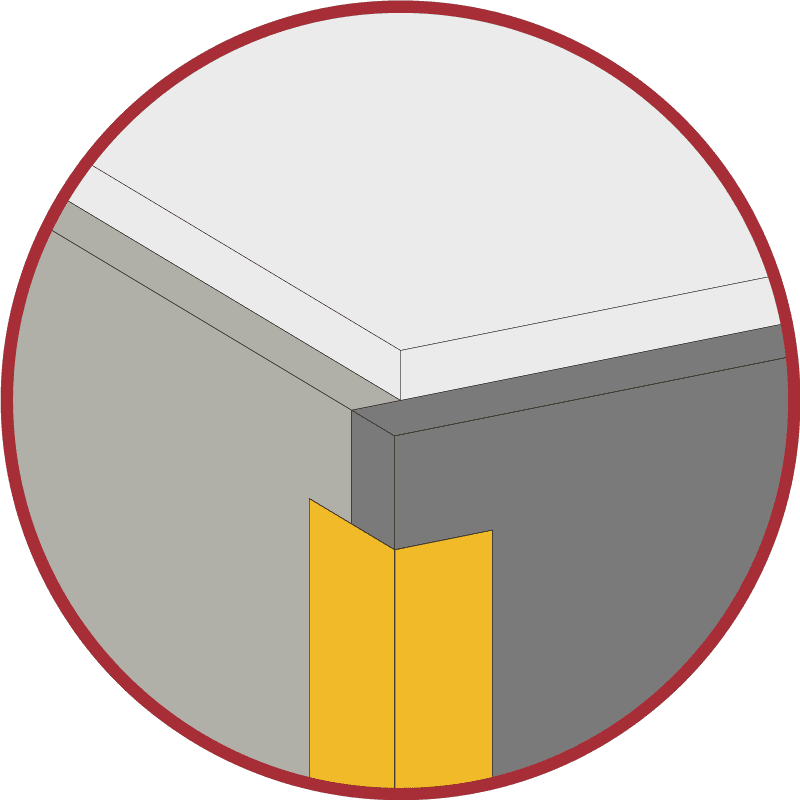

The experience in automatic rigid box making machines allows SATE to introduce new ways to produce different and innovative formats like the grooving boxes.

The grooving process creates V shaped channels that, when folded, make perfect ninety degrees edges.

This innovation is a step ahead in the production of high quality. luxurious boxes for high end products.